QUADRIGA•Film Examiner

Within a large film collection QUADRIGA•Film Examiner allows to identify the adequate preparation and scanning procedure for each archival film reel - based on their physical and photochemical condition. By utilizing the latest MWA spinner film scanner the examination procedure is extremely gentle to the fragile film substrate, so that typically the archive film can be examined without mechanical preparation or cleaning. A stabilized HD proxy file and a precise inspection report is generated on the fly to support a content-based triage process.

At a Glance

The Challenge

The prioritisation of archival film safeguarding based on the understanding of the physical and photochemical condition is an extreme labour- & cost intensive triage process. This has prevented mass digitisation of large film collections so far.

The Solution

A new intelligent software-driven film diagnostic system with already built in film inspection expertise. Highly automated examination procedure.

Results

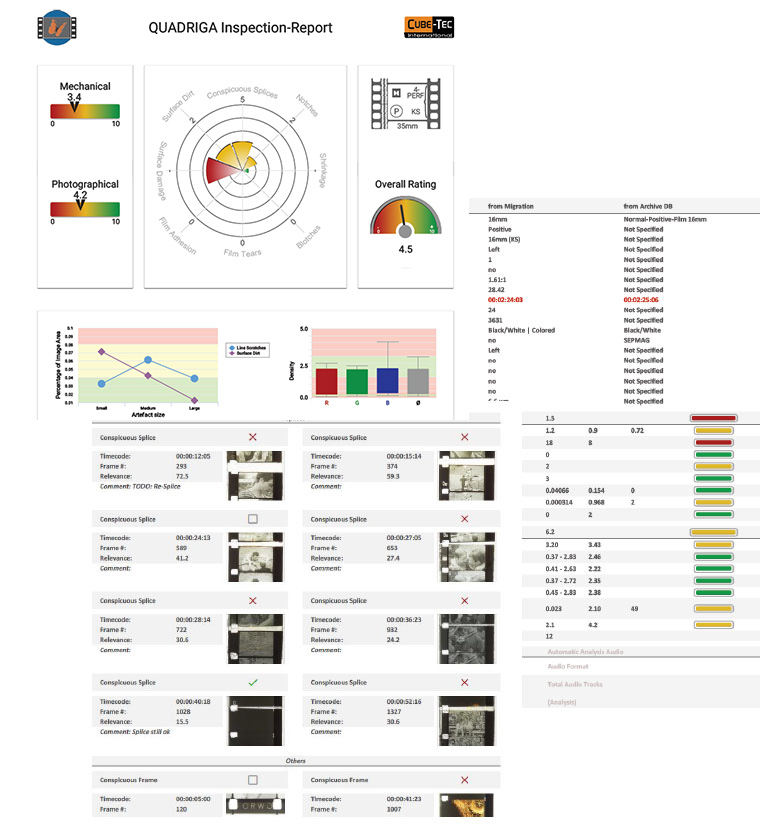

QUADRIGA•Film Examiner automatically provides a detailed inspection report with precise measurements of the physical and photochemical film properties together with an HD video proxy file for effortless film content triage.

Main Features

- Difficult splice handling

- Fused film layer handling

- Intelligent picture stabilisation

Automatic Control

Managing degrading and deteriorating film

- DPX

- JPEG 2000 mathematically lossless (optional)

- RAW (optional)

- AS-07 lossless preservation (optional)

- BWF/PCM audio 48 kHz/24 bit

- MXF H.264 image stabilized, image area only

Output Preservation Formats

Proxy format:

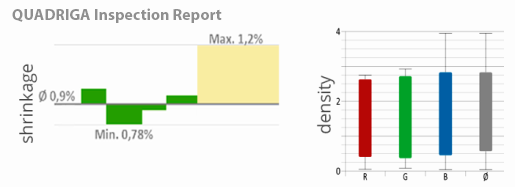

Measurements and Inspection Report

QUADRIGA•Film Examiner supports multiple measurement with laser and visual sensors including the new patent pending V-Black diagnostic sensor using a proprietary illumination technique. The V-Black diagnostic sensor completely separates the surface and carrier imperfections from the image content on the emulsion as well as on the base side. QUADRIGA combines digital image analysis and the analysis of the special sensor measurement data. This way the examination process works fully automatic. QUADRIGA’s Inspection Report documents precisely scratches, splice condition, notches, D-min, D-max, shrinkage profile…

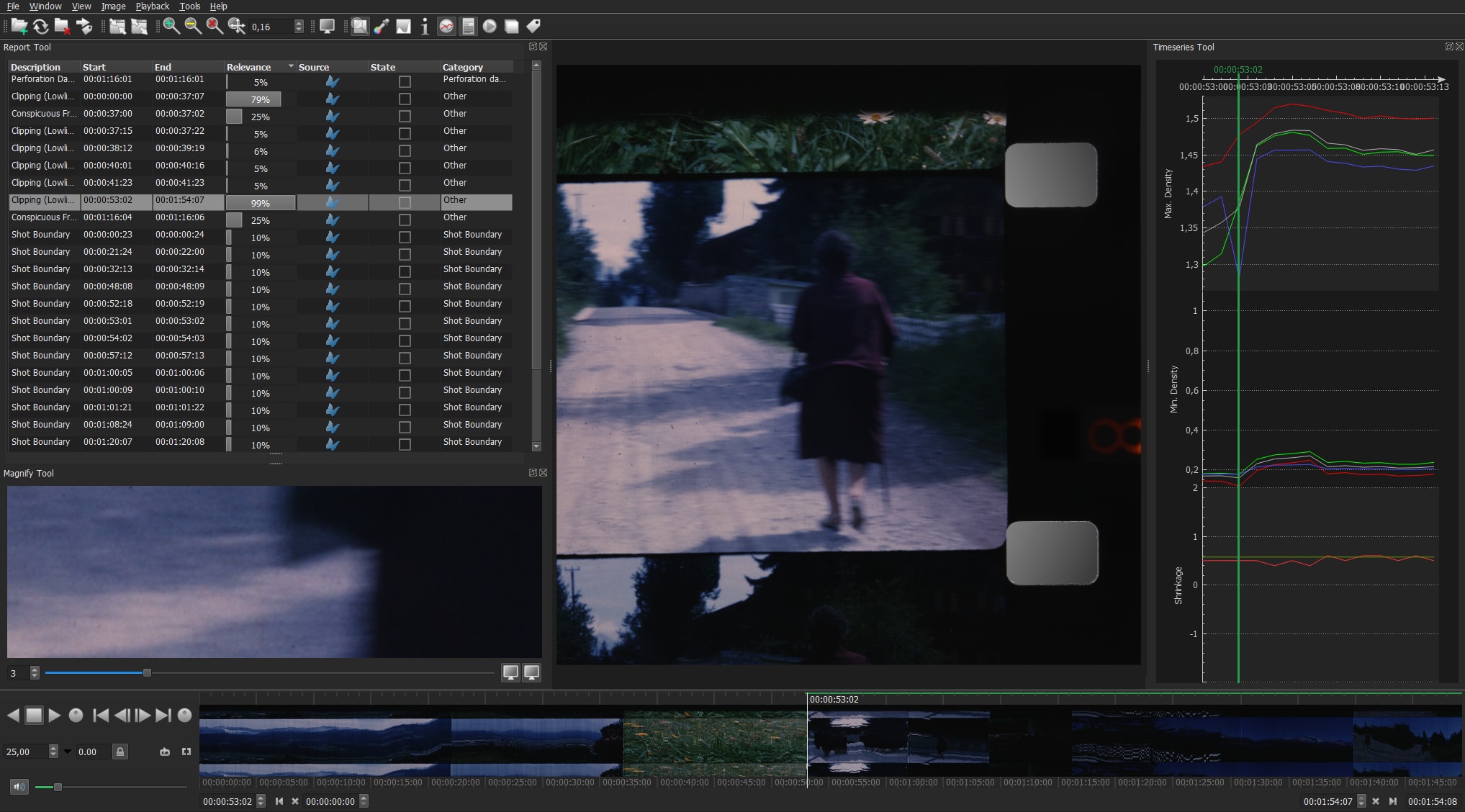

QUADRIGA QC View

QUADRIGA QC View report contains

Measures and documents amount of:

- Surface Dirt/Damage

- Emulsion Damage

- Line Scratch

- Shrinkage

- Perforation Damage

- Condition of bad splices

Counts the occurrence of:

- Number of bad splices

- Total number of frames

- Total film length with shrinkage

- Total film length without shrinkage

- Picture instability

- Number of shots

QUADRIGA QC View provides a frame accurate time series view of measures. Most important mechanical and photochemical film defects are automatically collected together with measures of imperfection on the optical scanning process read-out. Top defects are also visually highlighted in the QUADRIGA Inspection Report.

Full Feature List

- Synchronised frame accurate playback of the scanned DPX sequence, HD-Proxy file and frame related technical metadata in QUADRIGA QC View.

- Optical density of the film emulsion is measured on the fly for each frame and visualized in addition separately in three primary RGB colours.

- Film shrinkage profile is measured frame accurate and documented over the timeline.

- QUADRIGA works format agnostic up to 35mm, supports full edge-to-edge archive scan, or slight over-scanning with partly captured perforation holes.

- Automatically detects all common film formats and perforation hole types by analysing the image content and adjust the picture analysis accordingly.

- Remote control of MWA spinner film scanning devices.

- Surveillance of film scanner condition during image scan, results are logged for quality assurance.

- Sound Support for COMOPT/COMMAG/SEPOPT/SEPMAG

- Different codecs available for generating optional derivative media files.

- Top most mechanical film defects are automatically collected and visually highlighted in the QUADRIGA Inspection Report.

- Integrates well with existing catalogue databases and workflow management systems, integration with CubeWorkflow QC and file-based processing system.

- Optional Integration of additional deep inspection QC post-processing systems.

- Support for Calibration-Inspector•Film for automatic checking of the actual film scanner condition using the Cube-Tec calibration film with special test target analytics.

For the economical digitization of large film stocks, it is essential to have first a measure of the objective picture resolution on each of the archival film rolls in order to select an adequate film scanning procedure. But also to determine the correct digital storage requirements.