Calibration-Inspector•Film

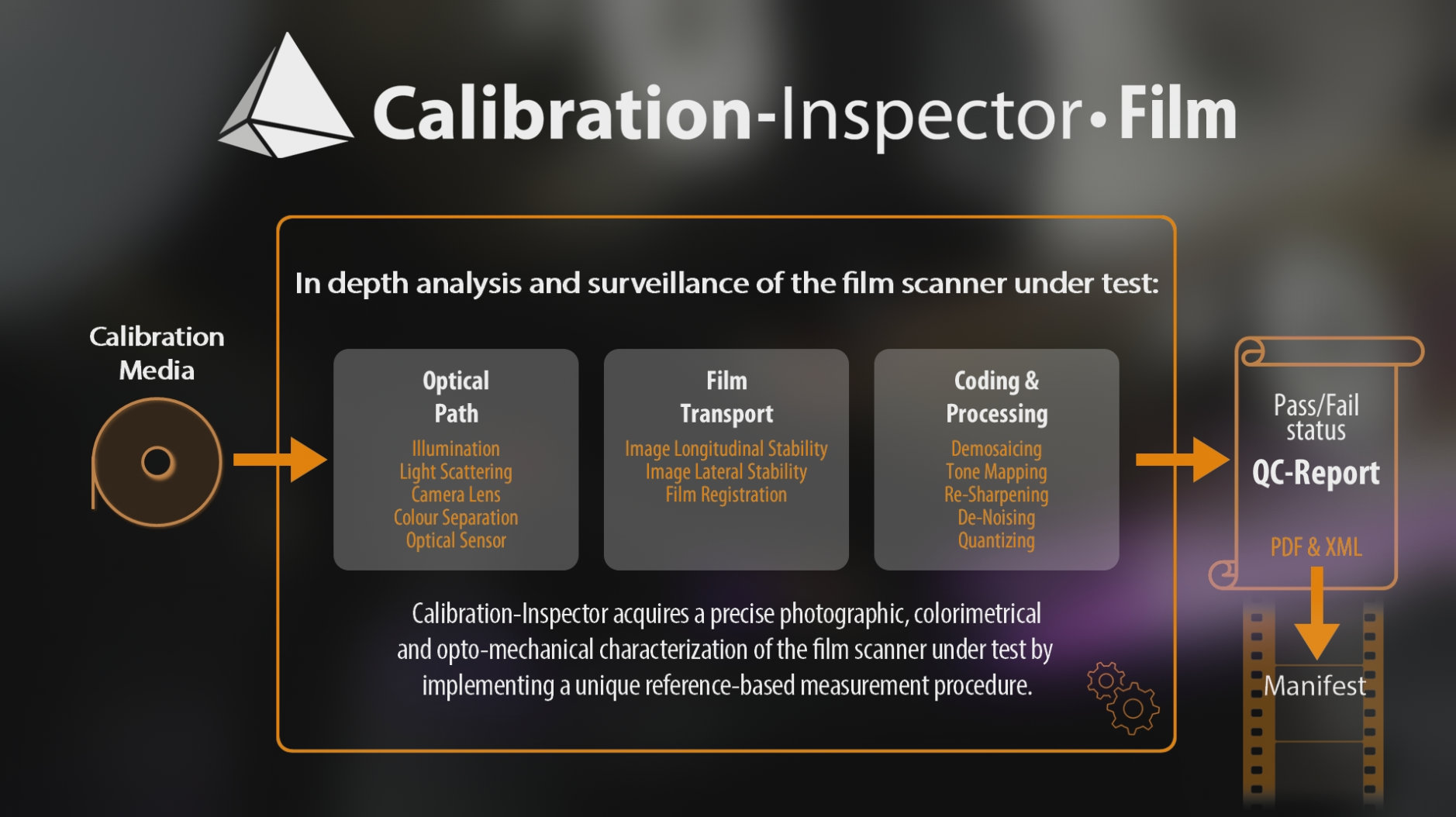

Based on a specially developed calibration film, Calibration-Inspector precisely measures and documents the current opto-mechanical condition of a film scanner. This happens within a fully-automated process. Calibration-Inspector should be used before any of the archive films are scanned. On the top level Calibration-Inspector•Film provides a pass-fail decision for the subject film scanner based on predefined quality thresholds. The detailed QC report enables deep drill-down into the technical details of the measurements performed.

At a Glance

The Challenge

The actual transfer characteristic of a given film scanner is unknown and cannot be documented as part of a film preservation action.

The Solution

A precise measurement device for extracting the quality defining attributes of the film scanner under test in an automatic process using a high-precision specially manufactured calibration film.

Results

Calibration-Inspector•Film performs state-of-the art objective measurements on unmodified film scanners and condense the measurement results into a meaningful quality rating system which precisely characterises the current opto-mechanical condition of the film scanner. Best is to include the this report into the film preservation master file.

Calibration-Inspector•Film Workflow

Calibration-Inspector•Film provides a human and a machine readable QC Report. The report documents the archived ‘transfer quality’ of the film scanner used and the measurements should be stored together with the preservation master files. This ’profiling data’ not only enables a judgement to be made as to whether the current condition of the film under test is in accordance with the agreed specification but also the 'profiling data' will enable future technology to correct - or at least diminish - imperfections in the film scanner of today.

Relation between QUADRIGA•Film and Calibration-Inspector•Film

As QUADRIGA•Film takes quality related measures while the archive film is scanned, the scope of application for Calibration-Inspector•Film is to characterise and document the current calibration status of the film scanner in use. Together they are the perfect couple.

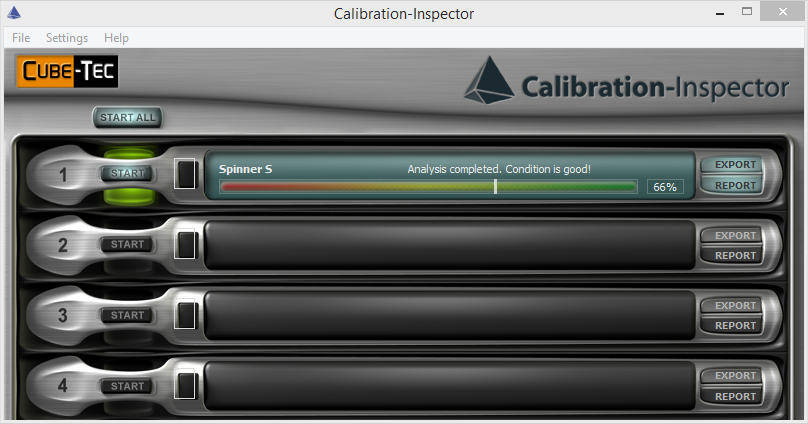

The top level of the Calibration-Inspector•Film graphical user interface is very lean and simple. It enables the analysis of the connected film scanner to be initiated and reports back the results of measurements and the state of calibration. When the report is opened deep drill-down into the measurements can commence…

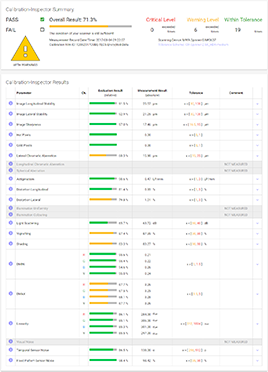

Calibration-Inspector Report

Calibration-Inspector•Film dashboard – summary of the measuring report. Quality Report available in human-readable (PDF) and machine-readable (XML) formats.

The Calibration-Inspector ’profiling’ data output has already enabled Cube-Tec’s development department today to provide a prove of concept to diminish some of the imperfections of the used film scanner.

Calibration-Inspector for a Digitisation Service Provider

If film scanning jobs are outsourced to ‘Digitisation Service Provider’ the use of Calibration-Inspector•Film provides a totally new level of insight to the technical condition of the scanning equipment used by the Service Provider – and this day-by-day for every reel scanned and without additional effort. Calibration-Inspector can be configured to automate the secure upload of the measurement values in an unadulterated format into the ‘Trusted Playback Quality Certification Service’. This cloud service gives the content owner, as well as the scanning service provider, secure read access to the technical and operational quality-describing data, providing dashboards and automatable notifications via e-mail and other communication tools if a configurable quality threshold is exceeded.

Thanks to Calibration-Inspector it is now possible for the first time, to explicitly define with your ‘Digitisation Service Provider’ the minimum required technical scanning quality parameters on a technically precise level within the respective service level agreement (SLA). And the Trusted Playback service ensures that you will be notified automatically as soon as one of the quality parameter is no longer in compliance with the parameter range.

The Trusted Playback Quality Certification Online Service can combine measurement input from QUADRIGA•Film migrations equipment, from Calibration-Inspector and can combine these inputs with process data collected by CubeWorkflow.

Archival Film Migration Done Right

- Manage the workflow with CubeWorkflow

- Migrate archival film with QUADRIGA

- Profile the film scanner with Calibration-Inspector

- Get insights and share all analytical metadata at Trusted Playback Online Service

Than you will discover what Aristotle already worked out: “The whole is greater than the sum of its parts” – this is archival film migration being done right!

Conceptual Archival Scanning Approach

Film scanner were originally invented to enable digital effects on filmed works. In contrast an ideal archive film scanner is not at all a creative manipulation tool. An archive film scanner has to perform a trustworthy and well documented reformatting process. Today's film scanners are still hybrids; the film transport approaches support for archival requirements but the signal processing is still optimised for generating a pleasing picture by performing 'some proprietary magic'. Calibration-Inspector demystifies and documents each ‘creative’ deviation from ideal linearity and documents deviations on all relevant parameters, enabling archivists to preserve and protect the authenticity of the filmed records.

Archival ethics require a two step approach. First scanning into a raw, unaltered preservation master file for long-term preservation. In a second step a colour corrected and otherwise ‘improved’ production copy optimised for the required output device can be generated for access. Since the requirements on output devices are changing drastically over time, this step is best performed on demand, driven by the preservation master file including the Calibration-Inspector records. Whether you can follow these archival ethics or not, Calibration-Inspector adds archival value with a precise description of the details of the signal alterations performed by the film scanner.

Supported Parameter

Quality Inspection Parameter (Image)

- Defective Pixels - Hot Pixels / Cold Pixels

- Image Sharpness (MTF-based)

- Geometrical Accuracy - Distortion Longitudinal

- Geometrical Accuracy - Distortion Lateral

- Lateral Chromatic Aberration (LCA)

- Vignetting / Shading

- Illumination Colouring

- Illumination Uniformity

- Luminance Linearity

- Colour Linearity R,G,B

- Optical Density DMIN (Red/Green/Blue/Y Ch.)

- Optical Density DMAX (Red/Green/Blue/Y Ch.)

- Temporal Sensor Noise

- Fixed Pattern Sensor Noise

Quality Inspection Parameter (Audio)

- Signal To Noise Ratio

- Azimuth

- Channel Balance

- Audio/Video-Sync

Pre-Check Detection

- Individual Calibration Film-ID (QR-Code)

- Test Sequence Integrity

- Dirt/Fingerprint/Film-Hair in the Optical Path

- Inverted Colours

- Image Flip Vertical / Horizontal

- Image Rotation

- Monochromatic Scan

- Highlight/Lowlight Clipping

- Image Cropping (Left/Right, Top/Bottom)

Overall Evaluation

- Calibration-Inspector – Overall Quality Factor

- Pass / Fail Threshold and Warning Thresholds

On premises or as part of the SLA with a Digitisation Service Provider – Calibration Inspector provides deep insights. It’s extremely easy to use and the measuring results are simple to understand even for non-experts and they are fully actionable.